In the spring, AAT received an order. It differed from our usual projects in its creative potential and the client’s great attention to details.

Awards that involved the entire production

The awards we set out to create should last for many years. After all, the recesses you see on the acrylic base are used to secure the medals – one every year. Calculate for yourself how many years the award should last if it has six recesses, one of which is already with a medal. And how long does it take for an award to serve as a memento? Here we are talking about decades…

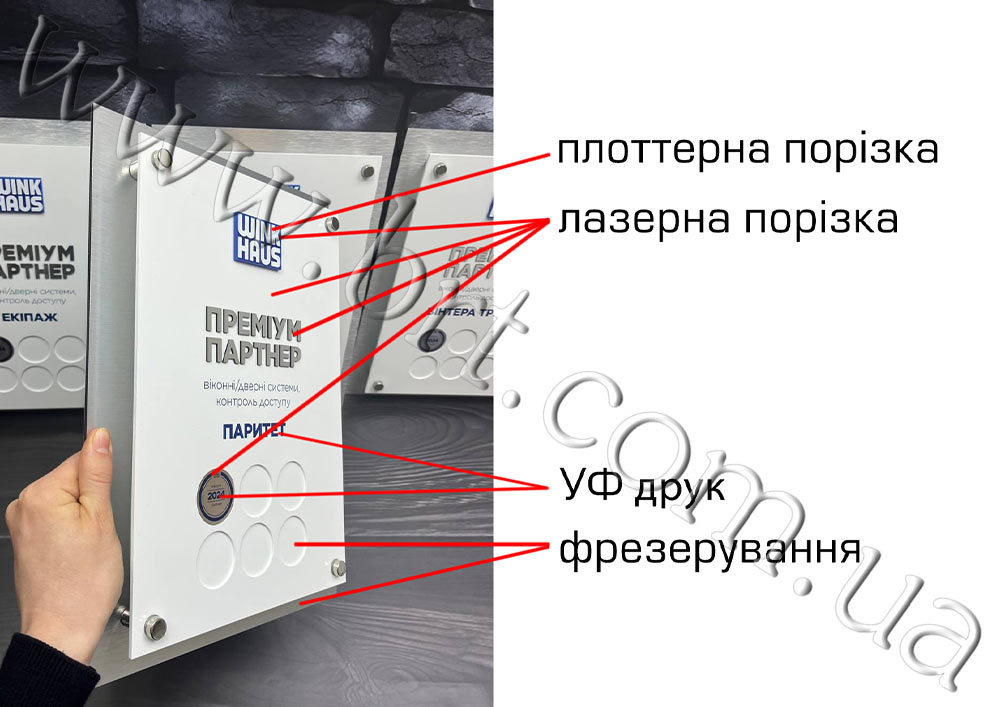

Another interesting point is that the recesses are needed in acrylic. That is, after the material was cut through on the laser, it was sent to the milling machine, where it was only slightly deepened. The laser cuts through the acrylic, while the milling cutter makes the notches in it.

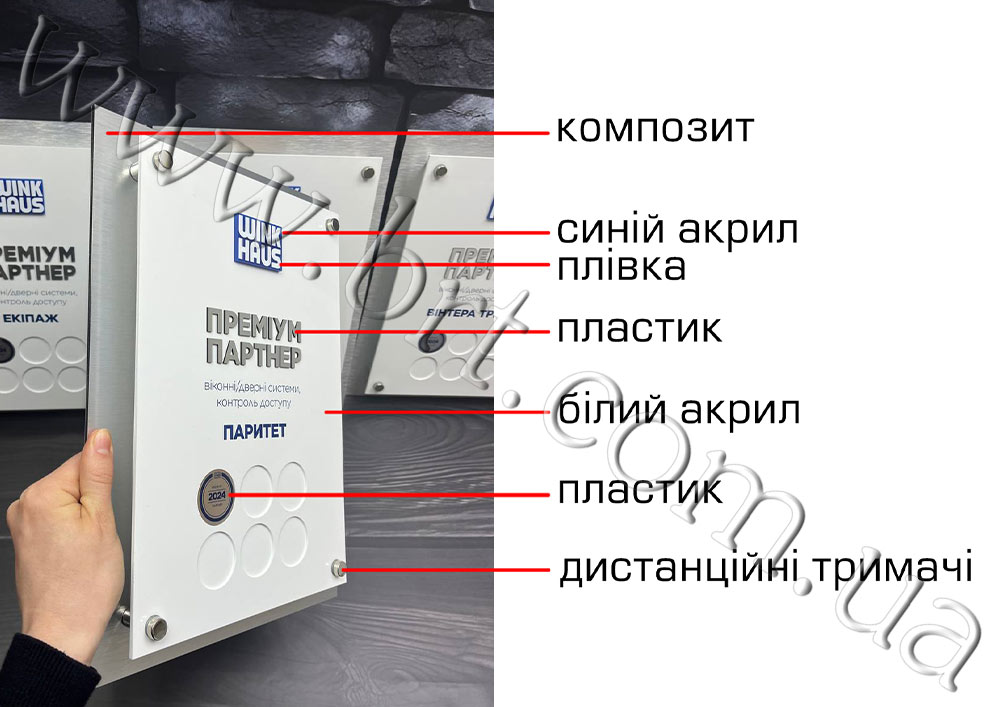

So, the first product was a test product. We carefully selected materials and production methods based on the client’s wishes and a photo example. The composite and acrylic, fastened with distance holders, harmoniously set off each other. And UV printing, one of the most modern and environmentally friendly production methods, has proven its reliability not for the first time. The successful result strengthened the client’s trust in us and we continued to cooperate.

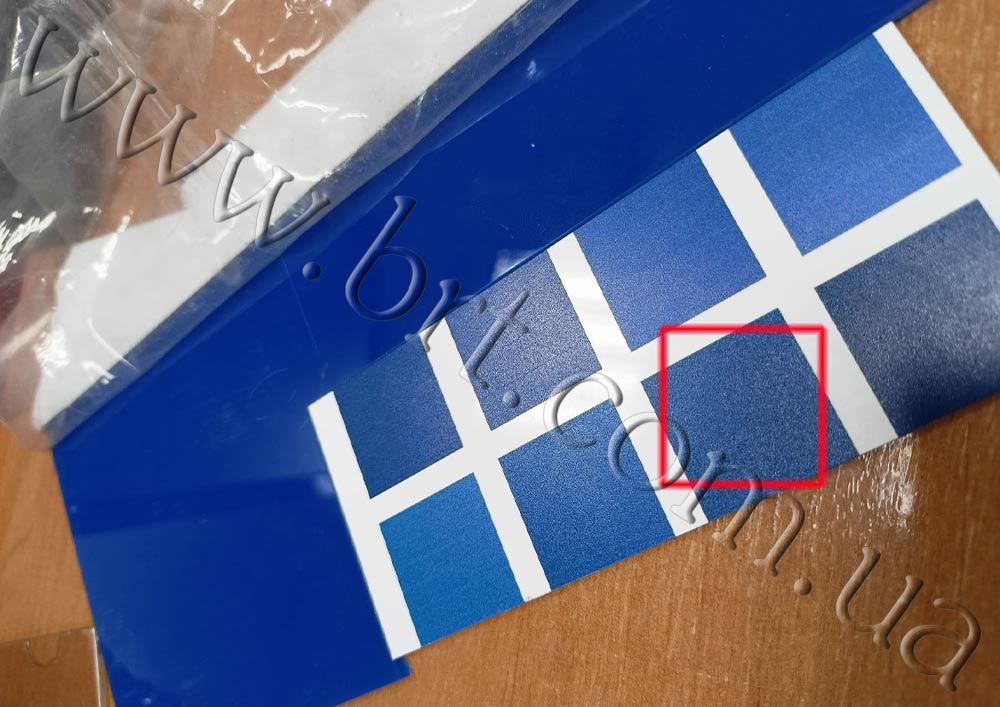

The next trial award was more detailed than the previous one: blue acrylic and white film were added to the design. This gave the product a more complex and three-dimensional look. We conducted several color tests to find the perfect shade of blue for the entire award. After all, the text on the award had to be approximately the same color as the piece of blue acrylic. Of course, it was impossible to achieve a complete match, because acrylic is a glossy material, and UV printing produces a matte finish. But this is not noticeable on the product itself. After completing the tests, we moved forward with full production of the awards.

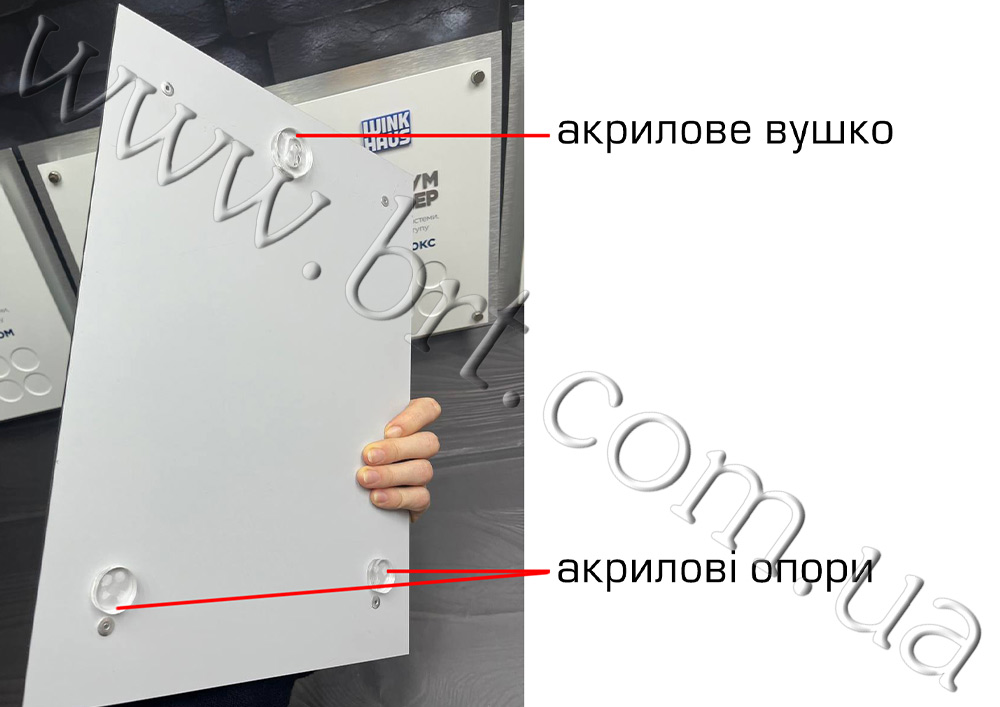

After the design was approved, more than twenty awards were created. Various materials were used: acrylic in two colors, silver plastic and composite, and film. Glue and distance holders were used to connect the elements, and acrylic eyelets and supports were used to mount them on the wall. All stages were performed using laser, milling machine, UV printer, and manually.

This project required efforts and resources from the production. The client ordered test samples and color proofs to achieve the best result. And the combination of our experience and skills, as well as the client’s understanding of his wishes, led to the fact that he was absolutely satisfied 🙂

By the way, you can see all the variety of awards from AAT here.